Cold Frame Enquiries: rudy@lonelybirch.com |

|

Page Last Updated: March 18, 2023 By: Rudy Racek |

| COLD FRAMES DESIGN BRACING BASES INTERESTED? UPDATES |

FORM AND FUNCTION |

|

|

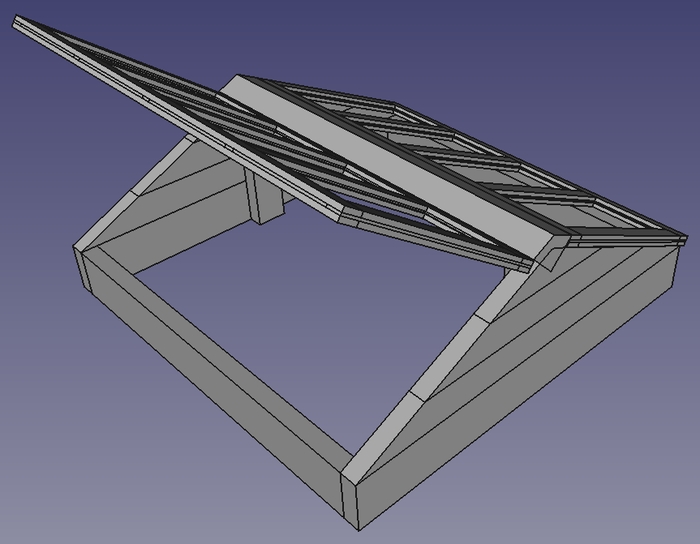

WHAT'S IN THE DESIGN? I wanted to make a cold frame that is practical, dependable and cost effective. Buying/producing it and fixing it should not break the bank. If you believe that the design is suitable for your gardening needs, feel free to get in touch and we can talk further. On this page I discuss my thoughts behind the main design elements of the frame. SIZE The nominal size (footprint) of my cold frames is 4 ft by 4 ft. The actual outer dimensions due to the size of lumber used is 50 inches by 50 inches. I am currently limiting myself to this size for the following reasons: 1) The weight of a fully assembled cold frame is approximately 120 lbs. This is great because it should allow simple and easy placement in the garden as anchoring should not be necessary even for high wind conditions. Creating a larger design will make it that much more difficult to handle manually. 2) In keeping the doors relatively robust and rigid, lengthening the doors would certainly add to their weight to the extent that their operation may become impractical. 3) Larger designs can make access to the plants inside rather cumbersome. Without the use of additional base sections, the highest growing clearance along the center of the cold frame is approximately 18 inches. The sloped roof design is intended to assist with rain and melting snow run-off. WOOD I recently fenced in my garden using mostly locally sourced tamarack for posts. I had some left-over pieces that lent themselves well to being milled further to create the parts that I needed for my design. While not everyone can afford cedar, tamarack is a more cost effective and local solution that should offer reasonable protection and durability for a good number of years. This should be especially true when a frame is used in conjunction with an easily replaced base which will effectively be the only part in direct contact with soil. More on bases HERE. In the future, I may experiment with other hardwood species such as maple as well. Other than the doors, the frame is constructed mostly of 2-inch thick rough cut wood around its perimeter. This contributes to its strength, weight and durability. Pressure treated wood is a non-starter in my opinion due the potential for unhealthy chemicals leaching into the very foods meant for human consumption. POLYCARBONATE The 2 cold frames that I have recently produced 1/4 inch thick double wall polycarbonate panels. You will see in different photographs of my designs that I am able to produce 2, 3 or 4 panes per door in order to optimize the use of my reclaimed panels from my short-lived greenhouses. See story HERE. Polycarbonate is a very tough and rigid material that, when installed correctly, should withstand the elements for many years. Other polycarbonate panels and thicknesses may be used in the future. Should a rock or branch accidentally cause damage to one of these panels, a small section of polyethylene plastic can be stapled temporarily to the door frame until a more permanent repair can be made. DOORS There are 2 doors, one on each side of the cold frame hinged on one sturdy wooden cross member. Many cold frame designs have only one door and therefore limit access to your plants inside. With this design, you shouldn't have to reach inside more than 2 ft per side. Door positions are adjustable and lock in place. The doors use the same wood as the main frame, but use a sandwich construction holding the polycarbonate panels in place with a combination of staples and screws. BRACING Door positions are adjustable and can be made to lock in place through the use of two wooden braces per door. The braces can be positioned to hold on to prepositioned screws along either side of the frame. Safe and stable door positioning is necessary for climate control as well as garden maintenance and must be reliable during gusty conditions. If the door is not secured properly using the braces, under the right conditions, a wind gust could do considerable damage to the door assembly. See more on bracing HERE. BASES Height and overall space are obviously limitations of any cold frame design, but some degree of flexibility is built into this design by employing an optional square base that can be attached on demand. Taking into account sunlight limitations, it is envisioned that one or two extra bases can be inserted and attached underneath the cold frame proper. This can increase your maximum growing height to a maximum of 30 inches. As separate components that make direct contact with the soil, if, over time, a base becomes rotten, it can be changed out relatively easily. Average base weight is approximately 50 lbs and each one adds a height of 6 inches. Another option that take advantage of the extra height gained through the use of multiple bases is the ability to raise the bed. While I personally will not be using the frames for raised beds this summer, this may be a possibility I may explore in the near future. See more on bases HERE. |

|